High Speed Steel Punches

Product Details:

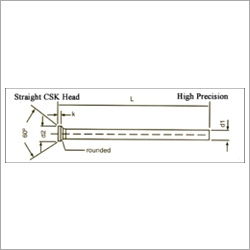

- Operate Method Manual or Mechanical

- Cutting Accuracy 0.01 mm

- Material High Speed Steel (HSS)

- Cutting Force Depends on machine capacity and punch size

- Brooches Type Round Punch

- Machine Type Punching Machine Compatible

- Length 25 mm to 200 mm

- Click to view more

High Speed Steel Punches Price And Quantity

- 20 INR/Piece

- 20-30 , , Piece

- Individual Box, Bulk Pack

- Mirror/Precision ground

- Silvery or as per coating

- ±0.01 mm

- Customizable as per requirement

- Available for size, shape, and coating

- Vacuum hardened and tempered

- Sharp/Flat/Radiused (customizable)

- Handheld and machine-mounted options

- DIN or as per customer specification

- Suitable for industrial die and tool making

- Good

- Sheet metal punching, forming, blanking

High Speed Steel Punches Product Specifications

- HRC 60-66

- Solid HSS Punch

- Up to 5mm sheet thickness (depending on material)

- Forged and precision ground

- High speed steel (HSS) suitable for rapid punching operations

- Punch Tool

- 1 mm to 30 mm

- Not specified, depends on application

- Uncoated / Customized

- Round Punch

- Depends on machine capacity and punch size

- High Speed Steel (HSS)

- Manual or Mechanical

- 0.01 mm

- Cold / Dry

- Optional (Uncoated/Coated)

- 25 mm to 200 mm

- Round

- Punching Machine Compatible

- Individual Box, Bulk Pack

- Mirror/Precision ground

- Silvery or as per coating

- ±0.01 mm

- Customizable as per requirement

- Available for size, shape, and coating

- Vacuum hardened and tempered

- Sharp/Flat/Radiused (customizable)

- Handheld and machine-mounted options

- DIN or as per customer specification

- Suitable for industrial die and tool making

- Good

- Sheet metal punching, forming, blanking

High Speed Steel Punches Trade Information

- 40 , , Piece Per Week

- 1 Week

Product Description

We are engaged in manufacturing and supplying quality range of High Speed Steel Punches that are offered in special shapes and sizes. These special shaped punches are fabricated only on specific orders with complete drawing with tolerance are required. We offer these products in the leading industrial prices. These are widely appreciated for its efficient performance, dimensional accuracy and long serving life.

High Speed Steel Punches Specifications :

| Use | Commonly Used as Cutting Tool Material |

| Material | Steel |

| Resistivity | Corrosion & Chemical resistant |

| Grades Available | T1, M1, M2, M7, M35, M42, M50 |

| Application | Power-saw Blades and Drill Bits |

| Type | Hollow Structural Section |

Superior Precision and Durability

Crafted from high speed steel and processed with vacuum hardening and tempering, these punches achieve outstanding hardness (HRC 60-66). The precision ground, mirror finish ensures accurate cuts with minimal burr formation, while strict adherence to 0.01 mm tolerance guarantees consistent results in demanding industrial environments.

Customizable for Versatile Applications

With options for edge type (sharp, flat, or radiused), size, shape, coating, and length, these punches support various sheet metal operations. Whether you require punches for manual tools or machine-mounted systems, customized solutions are available to suit specific production needs in die and tool making.

Optimized for High Performance

Engineered for both cold and dry operations, these HSS punches withstand rigorous punching, forming, and blanking tasks. Their high cutting speed and solid construction offer increased productivity, while corrosion resistance extends tool life, reducing overall maintenance and replacement costs.

FAQs of High Speed Steel Punches:

Q: How are the high speed steel punches manufactured?

A: These punches are forged and precision ground from high speed steel, followed by vacuum hardening and tempering processes to achieve optimum hardness and durability. Each punch undergoes mirror or precision finishing to ensure superior surface quality and tight dimensional tolerance.Q: What applications are these punches suitable for?

A: They are primarily designed for sheet metal punching, forming, and blanking, making them ideal for use in the die and tool making industries and compatible with both handheld and machine-mounted punch systems.Q: When should I choose a customized punch rather than a standard one?

A: If your operational requirements call for specific dimensions, coating types, edge geometries, or compliance with proprietary standards, custom punches offer a tailored solution to optimize performance and fit unique production needs.Q: Where are these high speed steel punches commonly used?

A: These punches are widely utilized across manufacturing facilities, fabrication shops, and tool roomsespecially within industries engaged in high precision sheet metal processing and component fabrication.Q: What are the primary benefits of using HSS punches with mirror/precision ground finish?

A: Punches with this high-quality finish offer smooth cutting action, reduced friction, and minimized burr formation. The precise finish also ensures repeatable results, extending the tools service life and facilitating clean operations.Q: How does the vacuum heat treatment enhance punch performance?

A: Vacuum heat treatment imparts uniform hardness and superior toughness throughout the punch, improving wear resistance and overall durability in high-speed or demanding punching operations.Q: What is the process for ordering punches with custom specifications?

A: Customers can specify size, shape, edge type, coating, and finish when placing orders. The manufacturer will manufacture and deliver to DIN or customer-drawn standards, offering individual or bulk packaging options as required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free